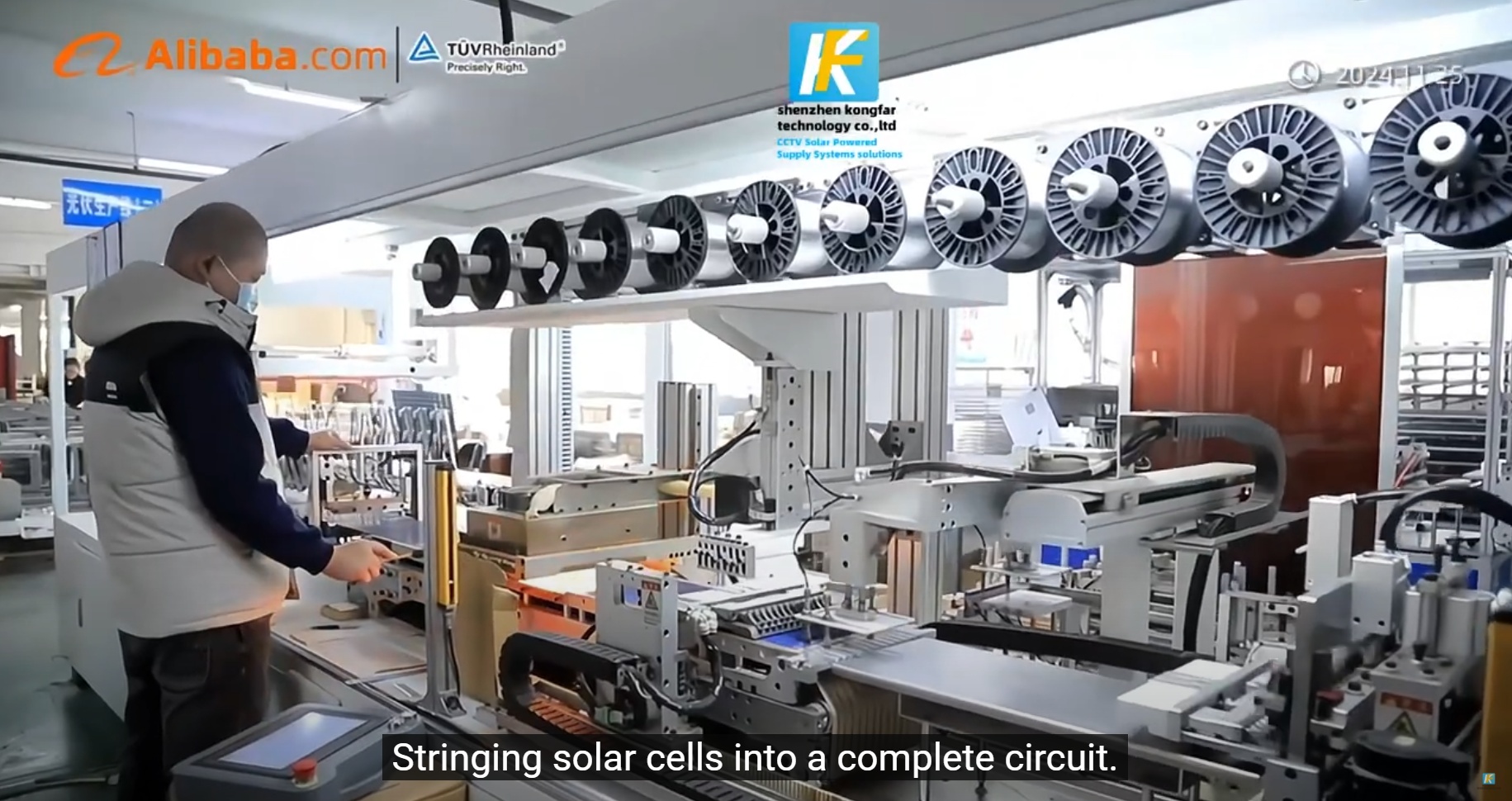

High-reliability solar CCTV systems start with accurate cell stringing. Our automated lines align and solder cells into consistent strings, controlling string tension, busbar wetting, and ribbon geometry to minimize series resistance and mismatch loss. The outcome is higher harvested energy for off-grid solar power kits that run PoE cameras, NVRs, edge gateways, and 4G/5G links in remote areas. Closed-loop vision checks confirm tab alignment and crack avoidance before strings move to interconnect and EL inspection, preventing micro-defects that could impact deployments in highway surveillance, rural electrification, or forest-fire lookout towers.

For partners needing a solar CCTV kit supplier from China, this automation delivers repeatability, which translates into predictable MPPT behavior and longer battery life in LiFePO4 systems. Documentation integrates with our CE files and ISO 9001 routing, making it straightforward to satisfy project audits for smart city programs and government frameworks that demand proof of process control and stable performance over multiyear lifecycles.