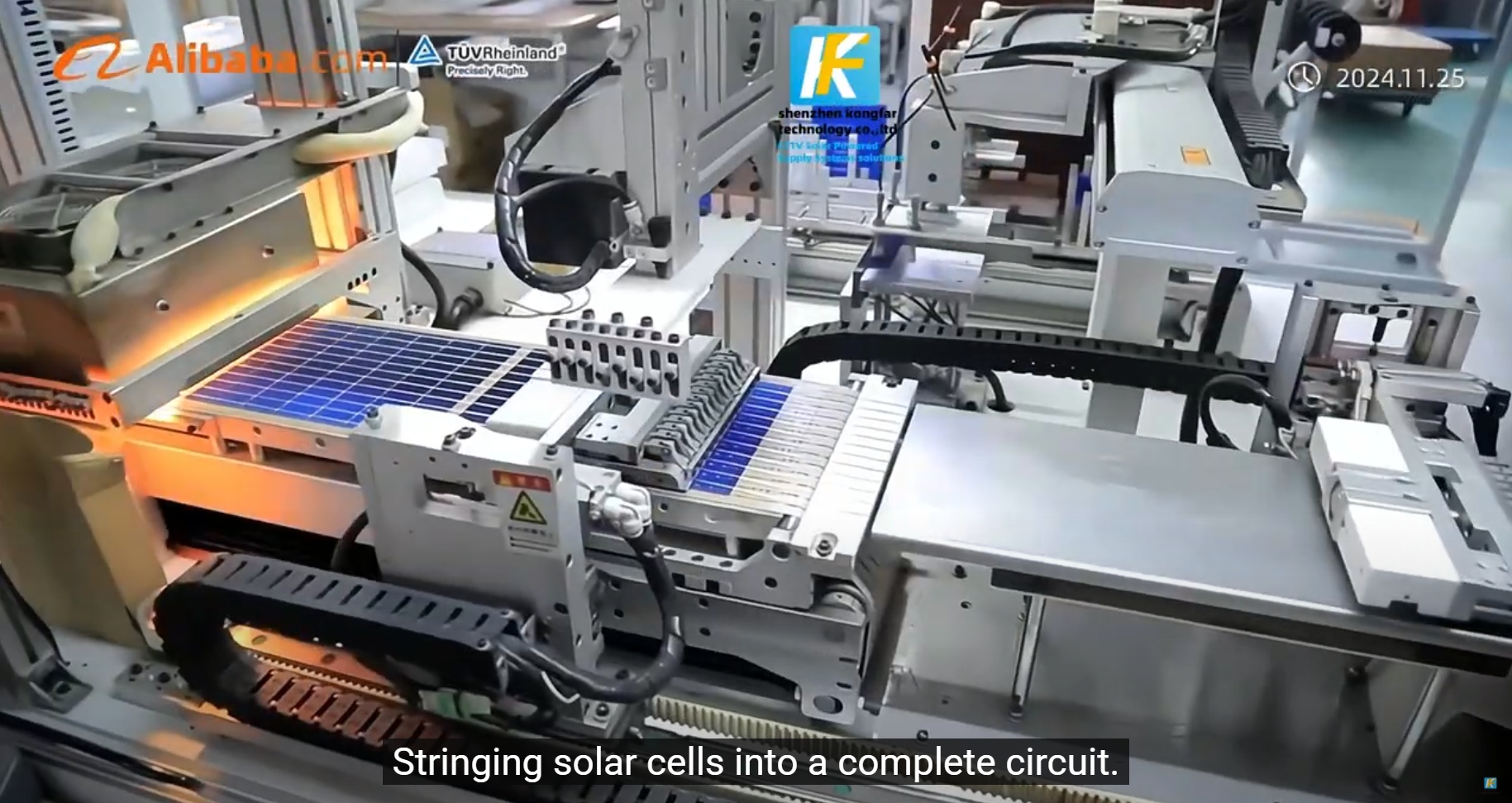

Our automated welding stage connects strings with precise thermal profiles and dwell times to protect metallization while ensuring low-resistance joints. We verify interconnect quality by EL imaging and pull-tests, then record parameters to each lot for traceability—a requirement many EU tenders enforce for CE-certified solar power kits. This precision pays off in the field: lower internal losses mean cooler operating temperatures and better MPPT utilization for off-grid surveillance systems powering pipeline monitoring, coastal defense, construction-site security, and mobile surveillance trailers.

As a China solar CCTV system manufacturer, we integrate welding data with downstream controller/battery sizing so the final kit—panel, MPPT, LiFePO4 pack, protection, and enclosure—arrives as a balanced system. Fewer thermal cycles and uniform current sharing extend module and battery lifetimes, reducing OPEX for distributors and system integrators tasked with 24/7 remote monitoring in harsh climates.