Autonomous Power Architecture Supporting Continuous Offshore Water Quality and Hydrological Monitoring

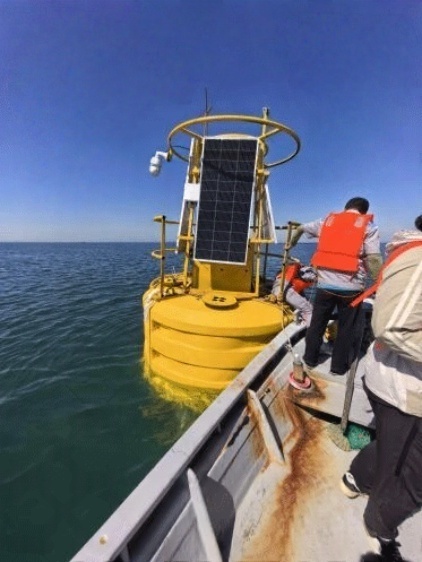

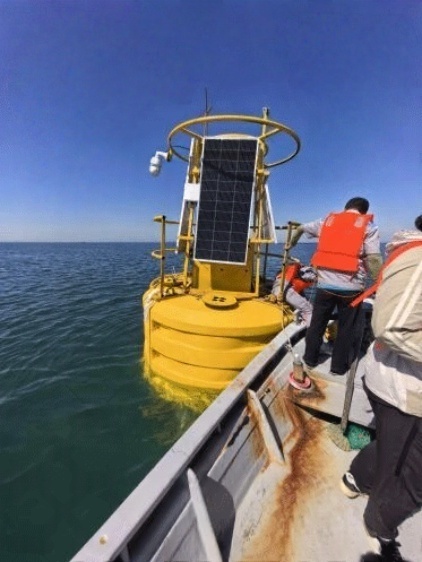

In offshore environmental monitoring projects in Dalian, Liaoning, floating buoys must support continuous operation of water quality and hydrological sensors under complex marine conditions. However, grid access is unavailable offshore, battery-only power has limited endurance, and harsh sea environments introduce challenges such as salt spray corrosion, high humidity, wave-induced motion, and seasonal typhoons. To ensure uninterrupted data collection and long-term system reliability, a customized off-grid solar power solution with dual capacity configurations was deployed to support diverse buoy monitoring loads across offshore areas.

An off-grid solar power system with dual photovoltaic and battery configurations, marine-grade protection, and intelligent remote energy management enables 24/7 buoy-based environmental monitoring in Dalian by overcoming grid absence, salt spray corrosion, wave-induced instability, and extreme weather conditions, ensuring continuous offshore data acquisition and reduced maintenance intervention.

Engineering Takeaways — Decision-Critical Insights for Off-Grid Solar Power in Marine Buoy Monitoring

The following engineering takeaways summarize how the off-grid solar power architecture addresses offshore environmental risks, operational constraints, and long-term reliability requirements in marine buoy monitoring projects:

1️⃣ Dual-capacity power architecture matches variable buoy loads: tiered configurations (800W/600Ah and 1200W/800Ah) ensure appropriate energy supply for both high-load and low-load monitoring equipment

2️⃣ Grid-independent solar energy enables continuous offshore operation: decentralized photovoltaic systems eliminate reliance on grid access or frequent battery replacement

3️⃣ Marine-grade corrosion resistance protects long-term reliability: salt spray–resistant coatings and sealed enclosures reduce degradation in high-salinity environments

4️⃣ Anti-sway battery compartment design ensures electrical stability: reinforced mounting prevents contact loss caused by wave-induced buoy motion

5️⃣ Remote energy visibility minimizes offshore maintenance frequency: real-time monitoring and automated alerts reduce vessel-based inspection requirements

6️⃣ Lifecycle costs are optimized through autonomous deployment: reduced battery replacement and fewer offshore service trips lower long-term operational expenses

SECTION 1 — Site-Specific Challenges for Marine Buoy Monitoring Deployment in Dalian

Marine environmental monitoring buoys in Dalian are typically deployed in offshore waters, exposed to seasonal typhoons, high salinity, and constant wave motion, far from any grid-accessible infrastructure.

Environmental and Operational Constraints

✅ Absence of grid access limits the feasibility of conventional power supply solutions

✅ High salt spray and humidity accelerate corrosion of power components

✅ Continuous wave motion causes mechanical stress and electrical instability

✅ Typhoon seasons increase the risk of power interruption and data loss

✅ Offshore deployment significantly increases inspection time and maintenance costs

Risk ImpactSalt spray exposure + wave-induced motion + grid absence → power instability → monitoring interruptions → data loss → reduced effectiveness of marine environmental supervision

👉 Continuous, marine-adapted and self-sustaining energy supply is essential to maintain offshore data continuity and monitoring reliability.

SECTION 2 — Power Architecture & System Topology for Marine Buoy Applications

Dual-Configuration, Marine-Adapted Energy Design

Component

| Configuration

| Engineering Purpose

|

Photovoltaic System

| 800W / 1200W solar array

| Matches varying buoy load requirements

|

Energy Storage

| 600Ah / 800Ah marine-grade battery

| Ensures endurance during cloudy weather and rough seas

|

Mounting Structure

| Reinforced anti-sway brackets

| Maintains electrical stability under buoy motion

|

Power Management

| Intelligent marine controller

| Optimizes energy dispatch and protects critical loads

|

High-power photovoltaic modules with anti-salt-spray coatings are mounted on reinforced structures to maintain generation efficiency under marine conditions. Battery systems are housed in sealed, corrosion-resistant enclosures with anti-sway reinforcement, ensuring stable electrical connections during buoy movement. Intelligent controllers enable balanced energy dispatch and continuous system protection.

SECTION 3 — Deployment, Operations & Risk-Control Efficiency

Offshore-Adapted Installation

✅ No grid extension or shore-based cabling required

✅ Reinforced mounting resists wave-induced vibration

✅ Corrosion-resistant enclosures protect against salt spray and moisture

Remote Visibility & Intelligent Alerting

✅ Real-time monitoring of photovoltaic output and battery status

✅ Automated alerts for abnormal power or system conditions

✅ Reduced reliance on frequent offshore inspection voyages

Lifecycle Cost & Risk Reduction Matrix

Factor

| Conventional Battery Supply

| This Project

|

Power continuity

| Limited endurance

| Continuous and autonomous

|

Corrosion resistance

| Poor

| Marine-grade protection

|

Maintenance frequency

| High

| Significantly reduced

|

Offshore service cost

| High

| Optimized

|

SECTION 4 — Measured Outcomes & Field Validation (Dalian, 2025)

KPI

| Result

|

System uptime

| 24/7 uninterrupted operation

|

Data completeness

| 100% continuous acquisition

|

Typhoon-season failures

| No failures observed during the monitoring period

|

Battery replacement frequency

| Significantly reduced

|

Validated during offshore deployment across multiple buoy monitoring sites in Dalian, including periods of high humidity and seasonal typhoon exposure.

Deep Search Intent Expansion — Engineering & Procurement FAQ

Marine Environment Adaptation

Can solar power systems operate reliably on floating buoys in offshore environments?

A: Yes. Reliability depends on marine-grade corrosion protection, reinforced mounting, and energy buffering. Salt spray–resistant materials and anti-sway battery design ensure stable operation despite continuous wave motion.

Power Endurance & Configuration Selection

Why are dual power configurations used for buoy monitoring systems?

A: Monitoring equipment loads vary significantly. Tiered configurations allow power systems to be matched precisely to device demand, improving efficiency while avoiding overdesign or undercapacity.

Maintenance & Cost Efficiency

Does off-grid solar power reduce long-term offshore maintenance costs?

A: Yes. Autonomous solar systems minimize battery replacement frequency and reduce vessel-based maintenance trips, significantly lowering operational costs in offshore deployments.

Engineering Decision Rationale for Marine Buoy Power Systems

Why solar power is preferred over battery-only solutions offshore

Battery-only systems require frequent replacement and increase offshore maintenance risk. Solar power enables continuous energy replenishment, reducing downtime and operational cost while improving monitoring reliability.

Engineering factors ensuring long-term offshore reliability

Key factors include salt spray resistance, anti-sway mechanical design, sufficient energy storage buffer, and intelligent power management tailored to marine conditions.

Scenarios requiring enhanced or hybrid configurations

In extreme offshore locations with prolonged low irradiance or additional sensing equipment, expanded storage or hybrid wind–solar configurations may be considered to ensure uninterrupted operation.

Related Smart-Infrastructure Energy Solutions

Forest Fire Prevention & Early Warning Power Systems

Solar-powered energy infrastructure supporting continuous wildfire detection, smoke sensing, and early warning networks across mountainous and forested regions with limited grid access.

👉 Explore solar solutions for forest fire monitoring systems.

Sand Mining Surveillance Power Systems

Off-grid solar power solutions enabling 24/7 surveillance, data transmission, and regulatory monitoring for sand mining operations in riverine and remote extraction zones.

👉 Learn more about solar power systems for sand mining monitoring.

River & Waterway Monitoring Power Infrastructure

Autonomous solar energy systems supporting continuous operation of water level sensors, flow meters, and river surveillance equipment along distributed waterways.

👉 View solar power solutions for river and hydrological monitoring.

Highway & Expressway Monitoring Power Systems

Independent off-grid power architectures designed for traffic monitoring, roadside surveillance, and infrastructure sensing along highways and expressways without reliable grid coverage.

👉 Discover solar power systems for highway and expressway monitoring.

Custom-Built Off-Grid Power Systems for Special Environments

Tailored solar and hybrid energy systems engineered to meet unique environmental, climatic, and regulatory requirements across diverse infrastructure scenarios.

👉 See custom off-grid power solutions.

Engineering & Procurement Contact — Off-Grid Marine & Infrastructure Power Projects

This section serves as the technical and procurement entry point for organizations planning offshore, marine, or infrastructure power deployments under complex environmental conditions.

Our engineering team supports site assessment, system architecture design, and deployment planning based on marine conditions, load profiles, compliance requirements, and long-term reliability goals.

Who This Is For✅ Marine environmental monitoring authorities

✅ System integrators delivering offshore sensing platforms

✅ Operators managing buoy-based or offshore monitoring assets

What Support Is Provided✅ Offshore feasibility assessment and system sizing

✅ Marine-grade corrosion and motion adaptation strategies

✅ Long-term reliability optimization and risk analysis

✅ Deployment guidance and lifecycle cost evaluation

Engineering & Procurement ContactEmail:tony@kongfar.com

Website:https://www.kongfar.comAll inquiries are reviewed by engineering specialists to ensure technical feasibility, environmental compliance, and long-term system performance before procurement decisions are finalized.